VFD is an acronym that is thrown around a lot when discussing energy savings and HVAC equipment. But what exactly is a VFD? How does it work? Why does it save energy? Hopefully this quick blog will answer these, and some of your other questions concerning VFDs.

A Variable Frequency Drive (VFD) is an electro-mechanical drive that is used to control the speed and torque of three phase AC motors. It does so by varying the frequency and voltage of the electrical current being sent to the motor. When the motor receives less voltage at a lower frequency, it will run at a percentage of its full speed, thus cutting back on the wear of the motor itself while using less energy in the process. Think of it like a dimmer switch on a light. If the room you are in is somewhat lit already, and you only need a little more light to make what you are doing more visible, you may just turn the dimmer up half way. The same concept applies to VFDs on HVAC equipment. For example, if you are running a supply fan inside an air handling unit for a system that contains variable air volume (VAV) boxes, and the spaces fed by many of the boxes are satisfied (the boxes are closed), the air handler will not need to put out as much air flow as it normally would. Simply closing the VAV dampers without slowing the fan is like driving a car with the gas pedal on the floor and using the break to control your speed. Doesn’t make much sense. By installing a VFD, you can slow down the supply fan and cut back on the energy usage.

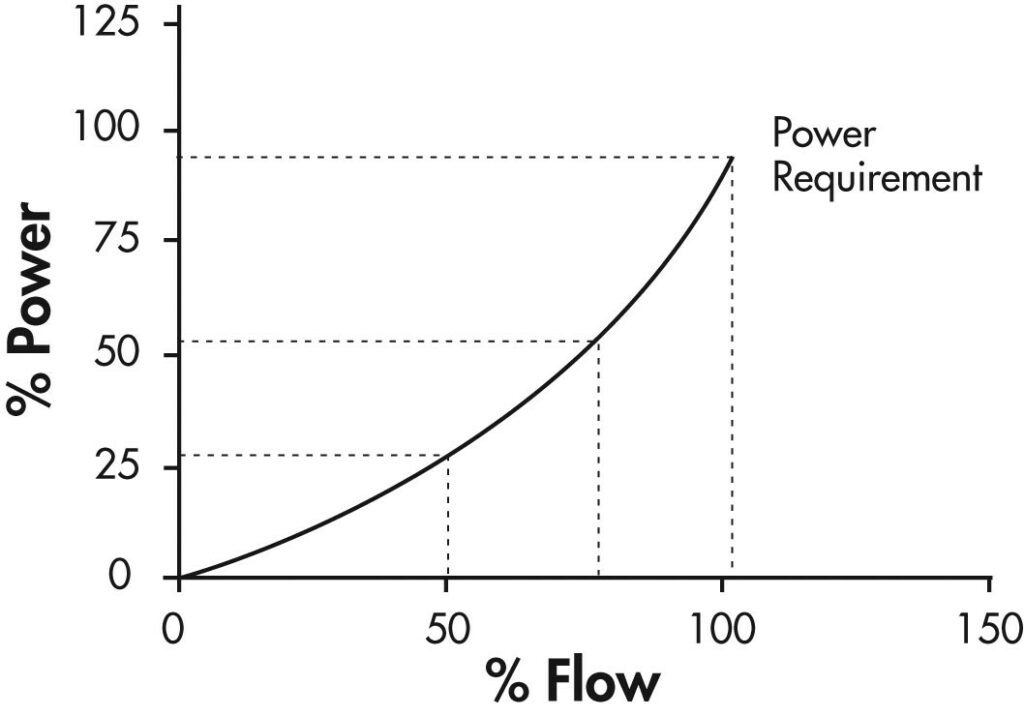

With the decrease in energy usage comes a decrease in costs. Even small cutbacks can have big impacts on the energy bill. In fact, VFDs for fan installations like the one discussed above could result in energy savings anywhere from 20% – 70%. According to affinity laws (relationships between pump or fan performance and power), a motor running at 63% of its full operating ability only uses about 25% of the power it would use if it was running at 100%. So a 37% decrease in speed causes a 75% decrease in required power.

According to IEEE “Eighteen percent of the energy used in the 40 million motors in the U.S. could be saved by efficient energy improvement technologies such as VFDs.” [1]

In addition to the cost of energy, properly applied VFDs can help lower maintenance and repair costs on equipment as well. The ability to “ramp up or down” a variable frequency drive when the demand changes will lower the amount of “starts and stops” on the motor. Frequent or excessive starts and stops can greatly shorten the life of a motor. VFDs can also be programmed to follow patterns when controlling a motor to help lessen the stress on the motor itself and to lower the amount of wear and tear on its mechanical and electrical parts.

If the potential energy savings isn’t enough, here are some other benefits of VFD:

- Many energy providers offer financial rebate incentives for VFDs

- Many VFDs have the ability to communicate with a Building Automation System (BAS) This allows for easy tuning and programming remotely

- Most VFDs are stand alone and do not require additional controllers

- Motors controlled by VFDs do not require a starter

- Many properly sized VFDs can control multiple motors

- Motors operated by VFDs usually have a reduction in noise level

It is estimated that 60% of motors used in HVAC application are NOT controlled by VFDs. With the savings in energy and maintenance costs, most VFDs will pay for themselves in as little as 1 to 2.5 years.

For more information on frequency drives, or to find out if your HVAC equipment could benefit from the addition of a VFD, call today!

Chris Ruth

636-680-2100

[1] http://ieeexplore.ieee.org/xpl/articleDetails.jsp?arnumber=4602695