Integrated Facility Services completed a complex, design build fire protection project to design, procure and install interior fire sprinkler systems for Blue Bell Creameries’ 16,000-square-foot distribution facility in St. Peters, Missouri. The state-of-the-art system was designed by IFS’s Fire Protection Department to ensure the safety and protection of the ice cream manufacturer’s facility and its occupants.

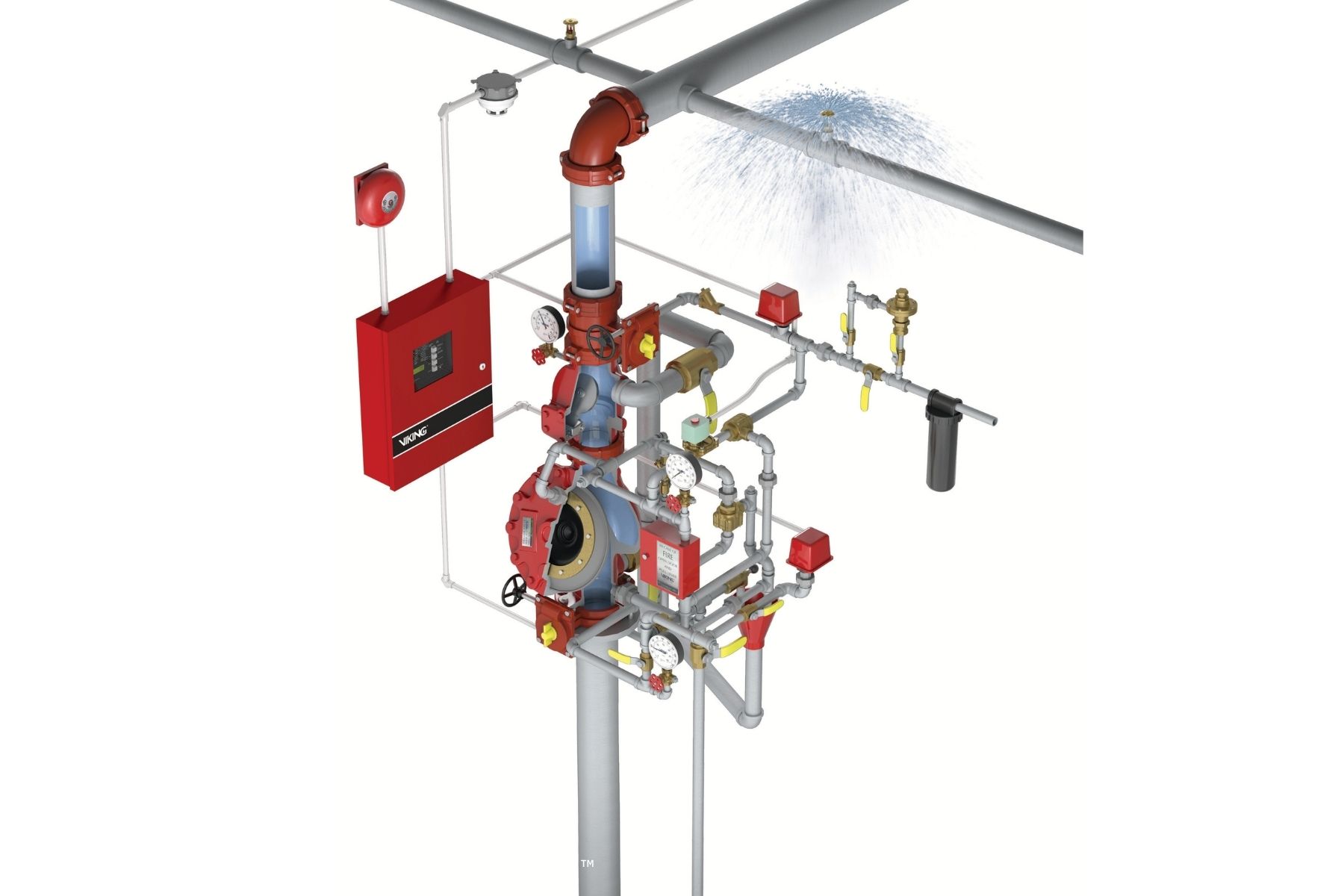

Key features include both a wet pipe sprinkler system and a double interlock preaction sprinkler system. To ensure a reliable source of water in case of fire emergencies, IFS installed an eight-inch spigot inside the building, supplemented with a remote fire department connection.